Sheffield forgings firm 'in strong position thanks to early and robust response to crisis'

and live on Freeview channel 276

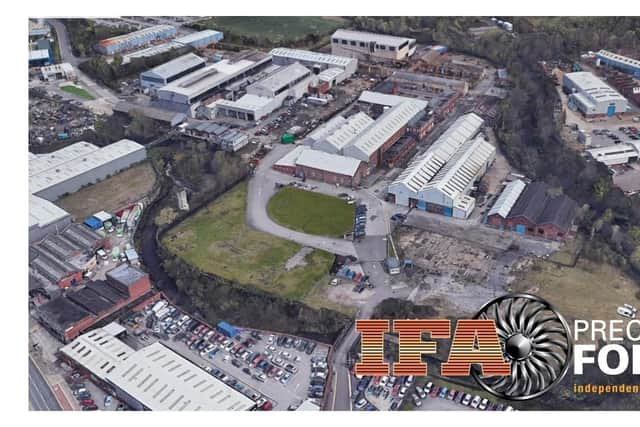

Independent Forgings and Alloys on Livesey Street, Owlerton, gave workers thermometers on March 11, 12 days before lockdown in the UK.

It was part of an approach that has seen the firm survive crises including the 2008 financial crash and the MERS and SARS outbreaks, bosses say.

Advertisement

Hide AdAdvertisement

Hide AdToday staff wear anti-virus snoods and face masks, and screens have been installed. Some staff have been furloughed, mainly volunteers. The plant is operating at 60 per cent capacity and can ramp up quickly.

But while aerospace and oil and gas orders are falling, the company is busy thanks to a strong order book.

And due to its “if it is forged we can do it" capability, it aims to pick up work in vital sectors such as power generation.

IFA employs 206 and before the crisis snapped up a complementary company, Doncasters Precision Forge and was in a “very good” position.

Advertisement

Hide AdAdvertisement

Hide AdHR manager Katy Edmonds said: “We are distinctly hopeful our business plan, which helped us survive 2008, SARS and MERS, will see us through this. We have got a lot of quality approvals across a lot of markets.”

The firm was buoyed by business secretary Alok Sharma writing to manufacturers urging them to keep working for the good of the nation. And customers in the supply chain have told IFA they are a key partner.

Meanwhile staff have pulled together.

Katy added: "Everyone was scared. It’s a lot to deal with. But everyone has been really supportive and taken their responsibilities very seriously. It’s challenging, but we are optimistic we can manage through this.”

Health, safety and environment manager Marius van der Colff said they knew coronavirus was going to be an international issue at the beginning of March. The firm issued thermometers with instructions to staff to take their temperature every day - and quarantine at home if they had symptoms.

So far for no employees have tested positive for Covid-19.

Advertisement

Hide AdAdvertisement

Hide AdHe added: “We are lucky that on the shop floor people work in small teams and can maintain a distance to limit the risk. Up to now production is keeping going. Some areas are virtually unchanged, in fact one team came in during spring shutdown becase it was so busy.”

In November, IFA bought the 30-strong Doncasters Precision Forge on an adjacent site and rebranded it IFA Precision Forge.

It now claims to be the only firm in the Western world with open-die ring rolling, press, hammer, rotary and closed-die forging, drop stamps and extrusions on a single site.

The same month, IFA joined the Sharing in Growth productivity scheme and announced plans to increase turnover from £23m to almost £42m by 2024.

Advertisement

Hide AdAdvertisement

Hide AdIn 2018 IFA received an £8.5m capital investment from the Business Growth Fund.

In January this year it invested in two LED billboards near its site at Owlerton. They were used to advertise jobs and news. Now they are used to thank the NHS and urge people to stay safe.

A message from the Editor:

Thank you for reading this story on our website. While I have your attention, I also have an important request to make of you.

With the coronavirus lockdown having a major impact on many of our advertisers - and consequently the revenue we receive - we are more reliant than ever on you taking out a digital subscription.